- Choosing a selection results in a full page refresh.

Sample Preparation

Sample Preparation

Biological Safety Cabinet

Biological Safety Cabinet

Laminar Flow Cabinet

Laminar Flow Cabinet

Fume Hood

Fume Hood

Freeze Dryer

Freeze Dryer

Steam Sterilizer

Steam Sterilizer

Vertical Pressure Steam Sterilizers

Vertical Pressure Steam Sterilizers

Lab Shaker

Lab Shaker

Open Air Shaker

Open Air Shaker

Stackable Shaker

Stackable Shaker

Floor Model Shaker

Floor Model Shaker

Test Chamber

Test Chamber

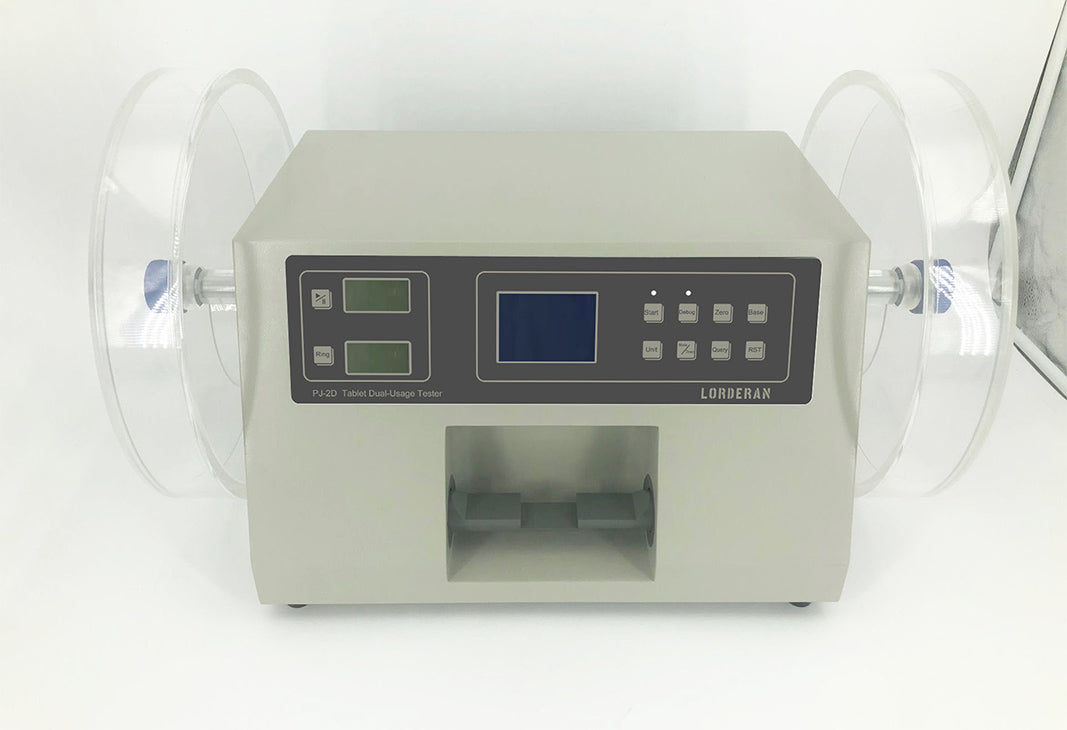

Tablet Testing

Tablet Testing

Warranty

Warranty Support

Support

FAQ

FAQ Blog

Blog My Wish List

My Wish List

Free shipping on all orders (Door to Door)

We can ship to worldwide. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

Learn more from our shippling policy https://www.lorderan.com/policies/shipping-policy

Delivered duty paid (DDP Term) shipping is a type of delivery where Lorderan paying for all charges including freight, duties, taxes, customs clearance charges up to the customer's door, warehouse or fulfillment center.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper, the time it takes us to process your return once we receive it, and the time it takes your bank to process our refund request (3 to 5 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item. Learn more from our refund policy https://www.lorderan.com/policies/refund-policy

Delivered duty paid (DDP Term) shipping is a type of delivery where Lorderan paying for all charges including freight, duties, taxes, customs clearance charges up to the customer's door, warehouse or fulfillment center.

| Model | PJ-2D |

| Testing Parameter | Hardness, Friability |

| Drum | 2 |

| Drum’s Radius | Dia. 286 mm |

| Drum’s Depth | 39 mm |

| Tablet Falling Height | 156 mm |

| Rotation Count | 10-900 r |

| Rotation Speed | 25 rpm |

| Speed Regulator Accuracy | ±1 rpm |

| Hardness Range | 2~199.9N (50Kg, 499.9N is optional) |

| Probe Procession Range | 3~40 mm |

| Power Supply | 220V/ 50Hz, 110V/ 60Hz |

| Power | 500W |

| Dimension | 360×450×350 mm |

| Weight | 15 Kg |

Thanks for subscribing!

This email has been registered!